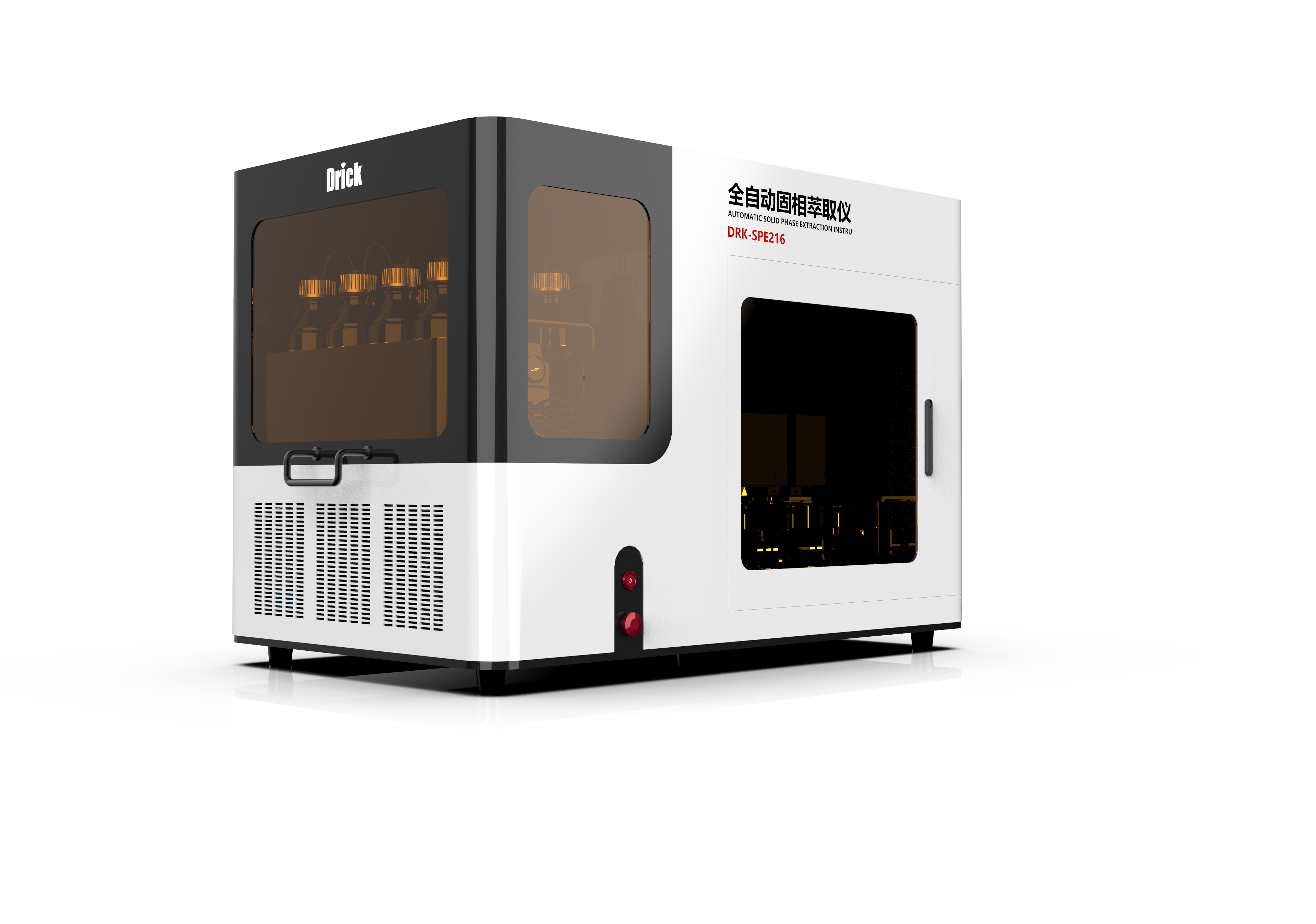

DRK-SPE216 Automatic Solid Phase Extraction Instrument

·Innovative three-dimensional four-axis mechanical arm design, taking into account flexible movement and precise positioning, can continuously process 52 samples;

·Pan plug sealing technology cooperates with H-axis compression block to realize high-pressure sealing and ensure the parallelism and reproducibility of samples;

·Highly integrated sample pump and piping system, compatible with large and small sample processing;

·Remote real-time monitoring, avoid contact with organic reagents during the experiment, and protect the health of operators;

·On-line concentration, on-line anhydrous sodium sulfate dewatering, making automation more thorough;

·Efficient cleaning technology, effectively avoiding cross-contamination.

Main functions and features

Number of channels:

The instrument host adopts a modular design, supports the number of on-site upgrade channels, and supports

1/2/4/6/8 multiple channel combinations;

Continuous processing capacity:

Maximum continuous processing of 52 samples;

Robotic arm:

The X/Y/Z/H three-dimensional four-axis mechanical arm design takes into account flexible movement and precise positioning, and the operating noise is less than 50dB. X/Y axis linkage improves operation efficiency; H axis is used to seal the extraction column to ensure the parallelism and reproducibility of samples;

Sample pump:

Accurate sampling, solvent corrosion resistance, high pressure resistance (pressure resistance above 1Mpa), and compatible with large and small sample loading;

Injection needle:

316L stainless steel material, solvent corrosion resistance; support liquid level following function; unique side-bottom opening method to ensure that all samples are loaded; highly integrated functions, can be used for liquid channels, gas channels, and also used for extraction column sealing;

Puncture sampling:

It can realize puncture sampling, avoid sample volatilization loss, protect the health of operators, and be green and environmentally friendly;

Remote connection and control:

The instrument is equipped with a router as standard, which can be connected via Wi-Fi or a network cable, which fully realizes the whole process of automation and unattended operation;

Sample volume and receiving volume:

All products support 10-20ml sample tubes, 50ml and larger sample tubes within two channels; receiving volume 10-15ml, 50ml and larger collection tubes within two channels;

Emergency stop button:

The instrument has an emergency stop button, which can be stopped in an emergency with one button to maximize user safety;

Flow rate control:

The instrument achieves high-pressure sealing through independent sealing cover and pan-plug sealing docking technology. At the same time, each channel is equipped with a pressure sensor, and the push column pressure realizes closed-loop fuzzy control, so that the solution passes through the extraction column at the set flow rate, ensuring good parallelism and reproducibility ;

Pressure Sensor:

With overpressure alarm and termination of the experiment function;

Solvent management system:

Support 8 kinds of reagents; real-time monitoring, prompt of insufficient remaining capacity;

Infiltration and incubation:

After the activation solvent or the elution solvent is loaded on the extraction column, the liquid level can be kept above the packing for a certain period of time to ensure full activation or elution, and to ensure that the ideal experimental results are obtained;

Cleaning mode:

Nitrogen purge, solvent cleaning, blowing and stirring cleaning and other modes are used to clean the inner and outer walls of the sample needle to avoid cross-contamination;

Waste discharge channel:

Support environmentally friendly recycling of waste liquids, and realize separate treatment of waste liquids of different properties;

Extraction column specifications:

Compatible with conventional l/3/6/12ml extraction columns, other specifications of extraction columns can be customized according to requirements;

Multi-scheme extraction:

Support different specifications of extraction columns and different processing items to set up and run at the same time, without waiting, improve the efficiency of continuous processing;

A/B column extraction:

Support multiple modes of string column extraction, and automatically identify the A/B column extraction scheme;

On-line drying/dewatering:

Support dual modes of nitrogen purge and online anhydrous sodium sulfate dewatering;

Online enrichment:

Support in-situ nitrogen purging and concentration, the concentration time can be edited, and the auxiliary concentration can be realized automatically;

Large volume injection:

Support the continuous and stable loading of samples above 500ml, without interruption, particle wear resistance, corrosion resistance, without any consumables and regular maintenance;

cloud service:

Support upload and download plans and parameters; support online technical support and communication;

Remote monitoring:

The instrument is equipped with a router as standard, which can be connected remotely via WiFi or network cable, which fully realizes the whole process of automation and unattended operation;

Appointment start:

After the experiment plan is edited, you can make a self-booking start time according to the analysis instrument machine time;

Intelligent self-check and alarm:

After the parameter setting is completed, the software self-checks whether there is a logic error, and promptly reminds the modification; the intelligent fault alarm system chooses to continue or stop according to the fault level;

| Model | SPE216 |

| Number of channels | 4 |

| Channel independent control | support |

| Sample pump | Precise continuous syringe pump |

| Pump flow rate | 0.1~120ml/min |

| Type of solvent | 8 kinds, 500ml independent solvent bottle |

| Loading volume | 0.1ml~20l |

| Sample tube volume | 10/20ml, other |

| Receiving volume | 10/15ml, other |

| Puncture sampling | support |

| Sample/solvent loading method | X/Y/Z three-dimensional robotic arm |

| Robotic arm accuracy | 0.01mm |

| Sealing technology | Independent sealing cover and pan plug sealing butt technology |

| Extraction mode | Positive pressure extraction |

| Extraction column pressure | 0-145psi |

| Pressure sensing | Support, overpressure alarm, editable threshold (5-145psi) |

| Drying method | Dual modes of nitrogen purge and online anhydrous sodium sulfate dewatering |

| Online enrichment | Support |

| Waste liquid collection | Split collection, 3 channels |

| String column | Support, A/B column |

| Cleaning mode | Various modes such as nitrogen purge, clear solvent, blowing and stirring cleaning, etc. are used to clean the inner and outer walls of the sample needle |

| Level following | support |

| Solvent remaining capacity | Real-time monitoring, reminder of insufficient remaining capacity |

| Size | 1005mmx622mmx720mm |

| Voltage | AC220/110V±10% 50~60Hz |

| Operating | 0~40ºC |

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top